Computational Fluid Dynamics (CFD) used to be a tool to develop highly expensive and complex products such as aircraft, rockets, ships, turbo machinery, etc. The tools were cumbersome, old fashioned and expensive. Models took a long time to develop and their usage was restricted to a selected group of highly experienced experts.

The last decade we’ve seen these boundaries degrade to the point that CFD tools are applicable to everyday product design. The improvement of user interfaces, integration with CAD tools and automation of various modeling tasks have brought down the entry costs. There’s still a steep learning curve, however CFD has become an invaluable tool for more and more industries.

Let’s take a look at an example in the Fast Moving Consumer Goods business. Maybe you’re familiar with at-home beer dispensers or coffee vending machines with a multitude of products. Most of these appliances contain some kind of cooling system to cool down at least some of the contained products.

Home beer dispenser development

Home beer dispenser development

These appliances are governed by requirements of low cost, minimal material usage, space allocation constraints and ever more stringent power requirements. Squeezing out the last bit of performance has become a non-trivial task which can no longer be done with empirical formulas and hand calculations only.

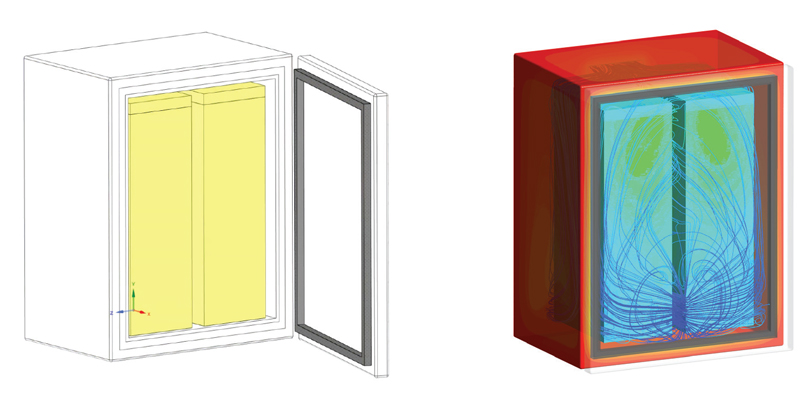

Generic coolbox design (left) and CFD simulation of internal air circulation (right)

Generic coolbox design (left) and CFD simulation of internal air circulation (right)

Here we show a generic coolbox design with internal air circulation which must cool down and keep cool 2 cardboard BIB containers. Hand calculations are fine to determine steady state conditions, but CFD can be used for so much more.

- Optimizing the placement of BIBs, air inlets and outlets for optimal airflow and cooling performance.

- Assessing the effect of cooling strategy on cool down time.

- Assessing the ideal control loop feedback for sensor locations.

- Calculating power requirements across various operating regimes and environmental conditions.

- Assessing the product temperature uniformity and prevention of product freezing conditions.

- Localizing cold spots which may cause condensation problems.

Building a single concept breadboard takes weeks and requires hundreds of hours designing, manufacturing and assembling. A CFD model however can provide answers in days. While a single cool down test takes hours, it can be simulated in minutes once a model has been created.

As such, CFD speeds up development cycles and delivers insights which are hard to obtain with empirical formulas and testing only.

Interested in finding out more on how Verhaert can apply simulations to your product designs or engineering problems? Get in touch.

Download the perspective

Looking for solutions to innovate?

Leave us your email and get in contact with Max van der Weyden, Manager Innovation Acceleration Services – Product Innovation, to help you with your innovation process.