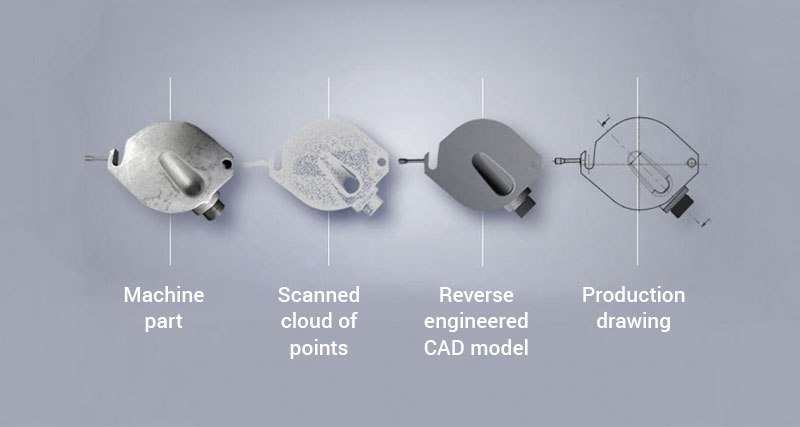

3D scanning, also known as structured or blue light scanning, is an advanced technology to perform quick surface scans at fast speed in clear High Definition quality meeting all your needs in reverse engineering, design verification, and production verification. With our blue light scanner, we help you to capture an accurate 3D dataset, contributing to the reduction of development time, resolution of challenging areas of the part, and cost minimization of parts, ultimately speeding up the overall time to market of your product.

What does blue light scanning do for you?

Blue light scanners are ideal to map your product or object of which no detailed and out-of-production drawings or 3D models exist. Because of its high accuracy, it’s perfectly possible to scan smaller, difficult, or untransportable objects with a high degree of detail: components, works of art, and precision parts.

The 6 stages of blue light scanning:

- Step 1: Creating a point cloud.

- Step 2: Creating an open mesh model (by scanning software).

- Step 3: Creating an iges file.

- Step 4: Creating a closed mesh model/processed STL file (engineering).

- Step 5: Creating a STEP file (engineering).

- Step 6: Creating a native CAD file with intelligence (engineering).

5 benefits of digitizing your reality

- Fast scanning – The extra-wide scan line and fast capture rate increase productivity by extending the range and reducing scan measurement time.

- Scan complex materials – Seamlessly scan over a variety of surface materials (regardless of contrast, reflectivity, or complexity), without the need for special coatings because of the enhanced HDR (High Dynamic Range) mode and advanced software algorithms.

- High Definition data – Complex components can be captured in detail, thanks to exceptional scanning performance of up to 560.000 points/second, and by the new blue laser with noise reduction technology.

- User-friendly – The Crosshair and LED rangefinder function provide real-time scanning feedback.

- Very high accuracy and repeatability – Reliable, repeatable, and highly accurate measurements thanks to superior optical performance.

Accelerate your product innovation

Verhaert uses the versatile FARO Edge ScanArm HD which is the world’s most advanced, intuitive, portable measurement system for non-contact measurements.

Curious about the countless possibilities of blue light scanning? Get in touch with Max Vanderweyden or Jeroen Raeijmaekers.